Engineering & Quality

Technical know-how, design and experience in producing valves are our strong assets thanks to a highly experienced team of valve engineers, a professional approach to design and a deep knowledge of advanced software.

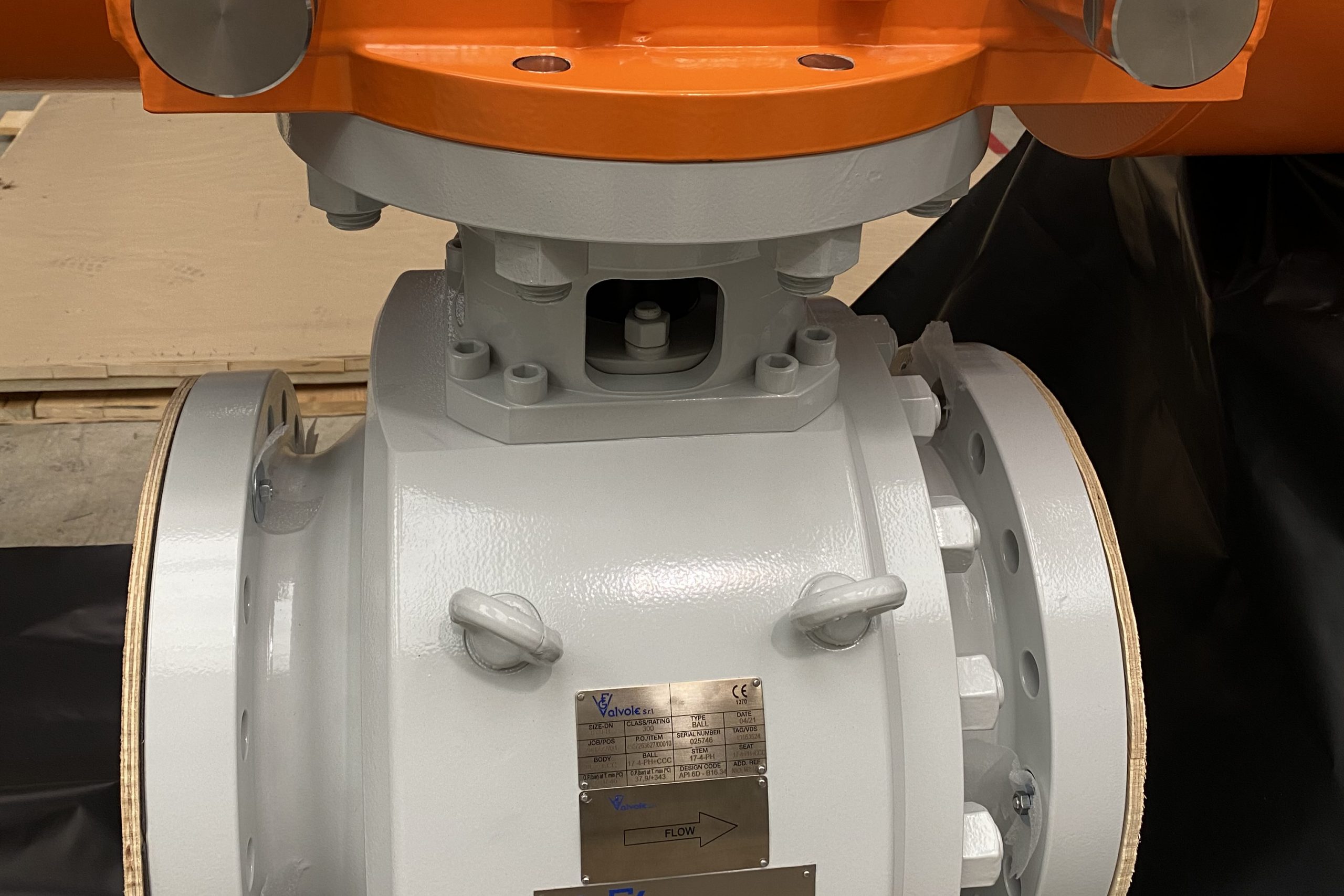

Our team of Engineers is able to develop valve design according to various Customers’ needs, both standard and for special applications such as: high pressure services up to API 20000, cryogenic services, special seals, modular DBB valves, Sub Sea, HIPPS and ESD applications.

Technologies

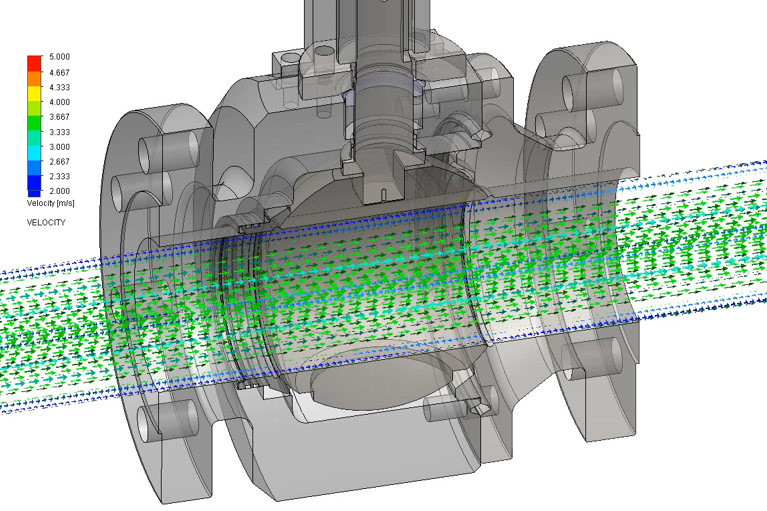

Software

Engeneering software tools with Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Ansys CFB, Flow Analysis, CAD 3D (Solidworks)

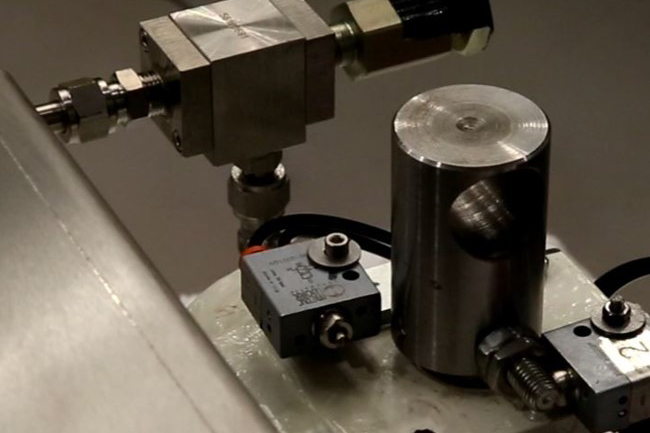

Testing Equipment

9 Test Benches in house. All bunker equipped with cameras and Oxygen level control in accordance with highest safety requirements

Remote Testing

Test performances can be transmitted online through wifi connection in case witness inspection can not be arranged

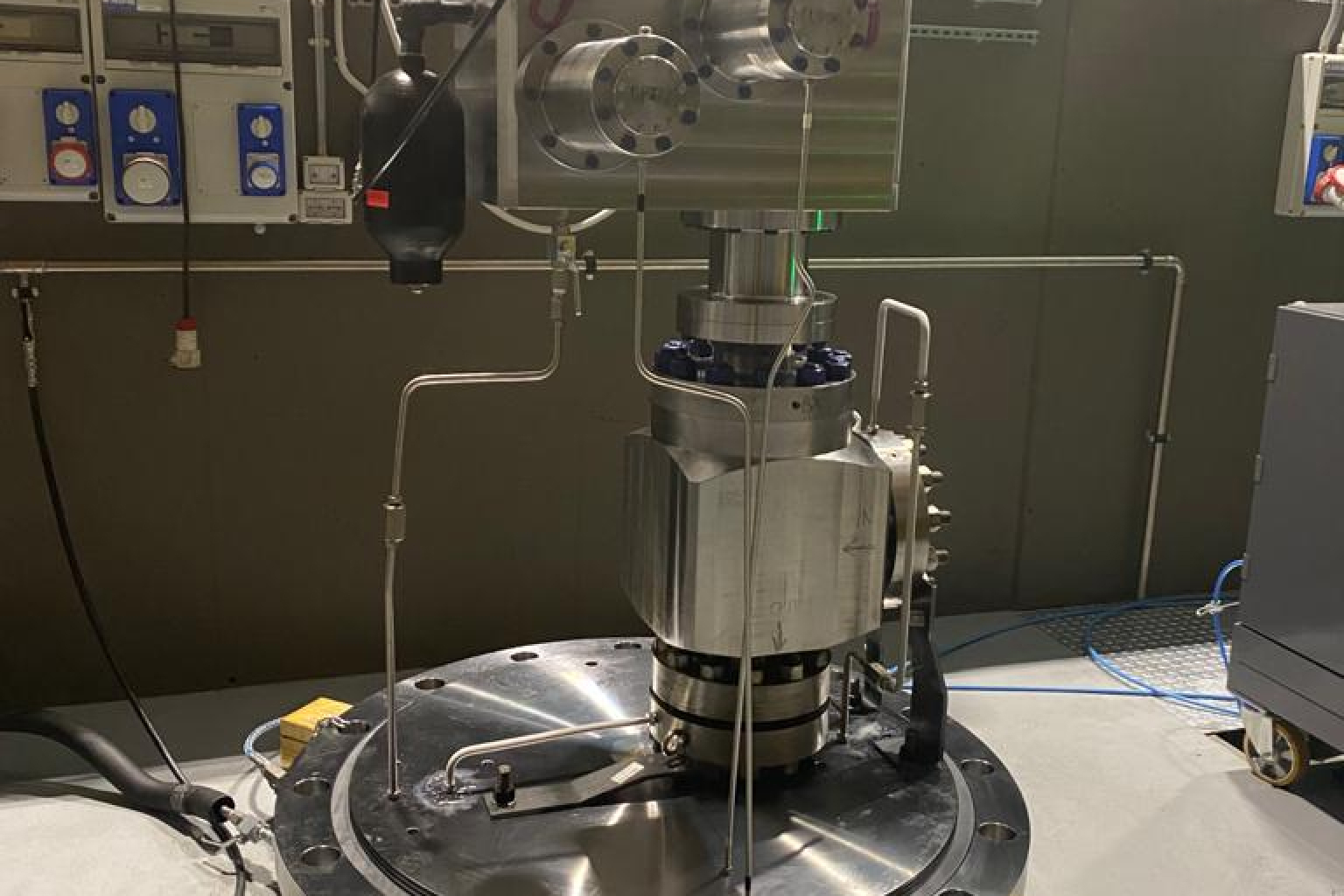

Subsea Actuator Testing Bunker

Subsea valve and actuator testing equipment

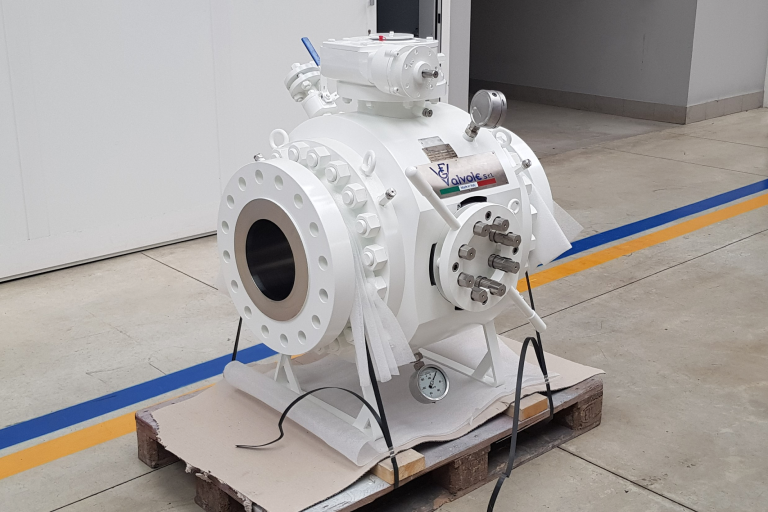

60 Inch Test Bench

Our biggest test bench can fit up to 60 inch 300 or 48 inch 600

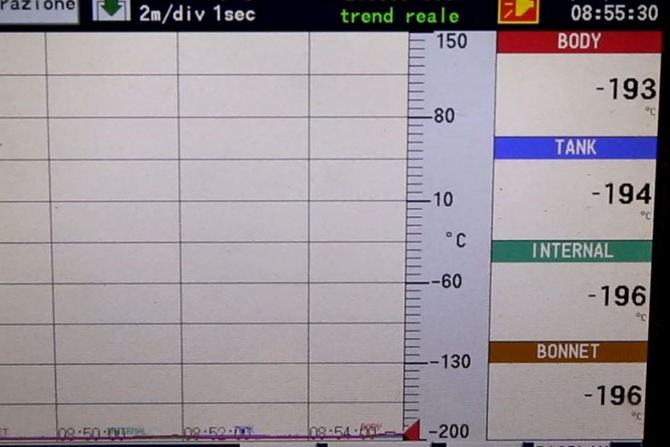

Cryogenic Tank

We have two cryogenic tanks available where we can perform tests up to -196 Celsius degrees

Hyperbaric Chamber

Suitable for 500 meters water depth

Multidirectional Cart

Heavy duty trolley up to 65 allow us to move easily big valves throught the production process

R&D

R&D is important for us because it provides powerful knowledge and insights, leads to improvements to existing processes. Innovation activities concern both the techniques used to obtain a product (Process innovation) and the product itself (Product innovation). In this scenario the R&D department has played a relevant role in finding the right solution for clients. Every year FG Valvole invests more than 10% of its turnover to support innovation.

Subsea Slab Gate Valves API 5000

Subsea Slab Gate Valves are designed with the help of the most updated technologies to guarantee maximum reliability and accurate tightness for an extended cyclic life operations.

Each valve is designed in full accordance with ASME VIII Div. 2 App. 4 (full FEA) with additional requirements of ISO 10423. All FEA evaluations are carried out in FG Valvole or under strict experts supervision.

High Cycles Cryogenic Test

Floating and Trunnion Ball valves with Pneumatic actuator tested at -196 Celsius degrees Operable Condition for a total of 10.000 cycles for LNG Batch Loading Process

Scaper Valve for Offshore Platform

A type of valve capable of replacing the use of both Pig launcher and receiver with less cost of maintenance and ideal in case of limited space available such as Offshore Platform. The pig can be insert directly on the side of the valve by removing the plug in a depressurised cavity, in a totally safe condition.

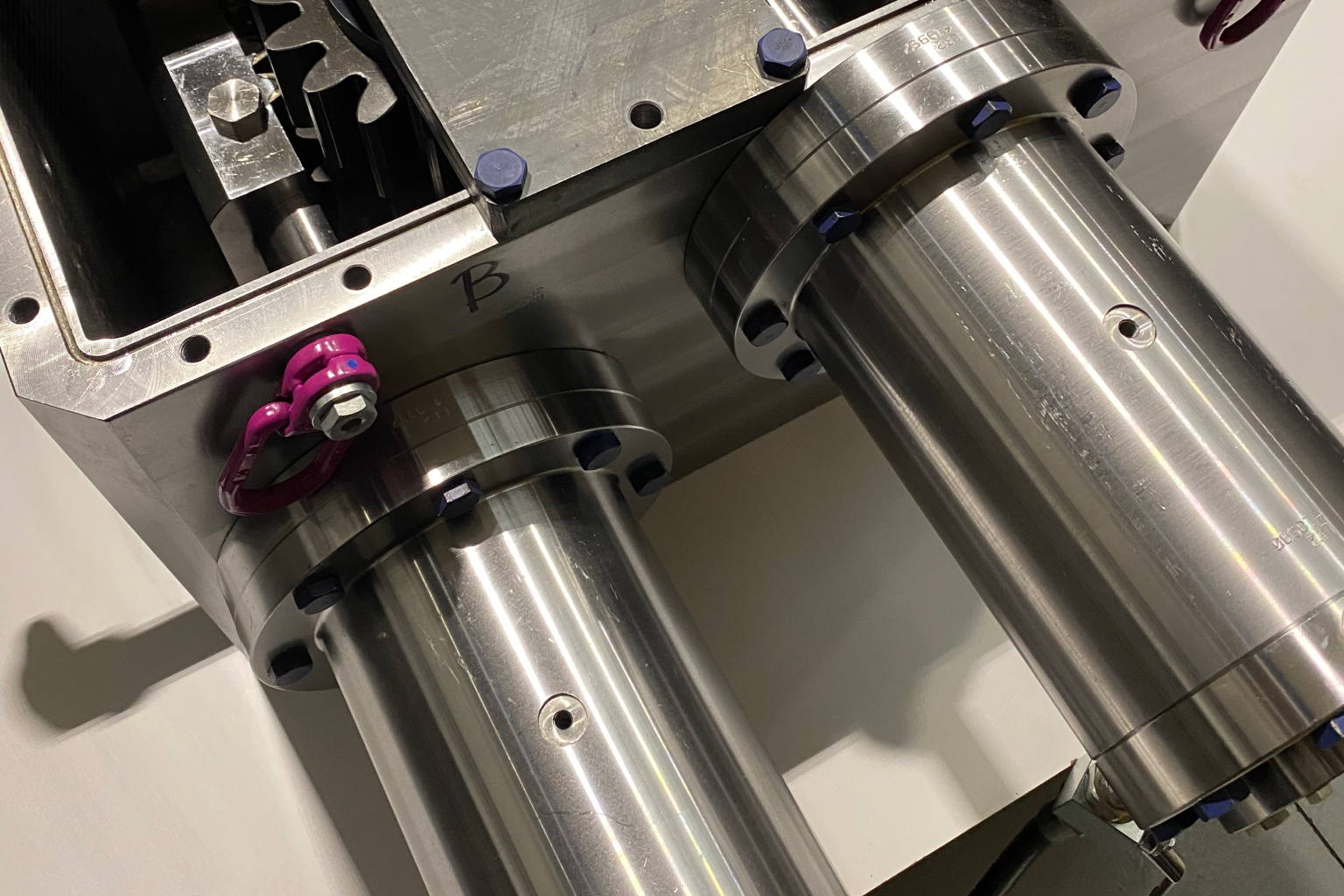

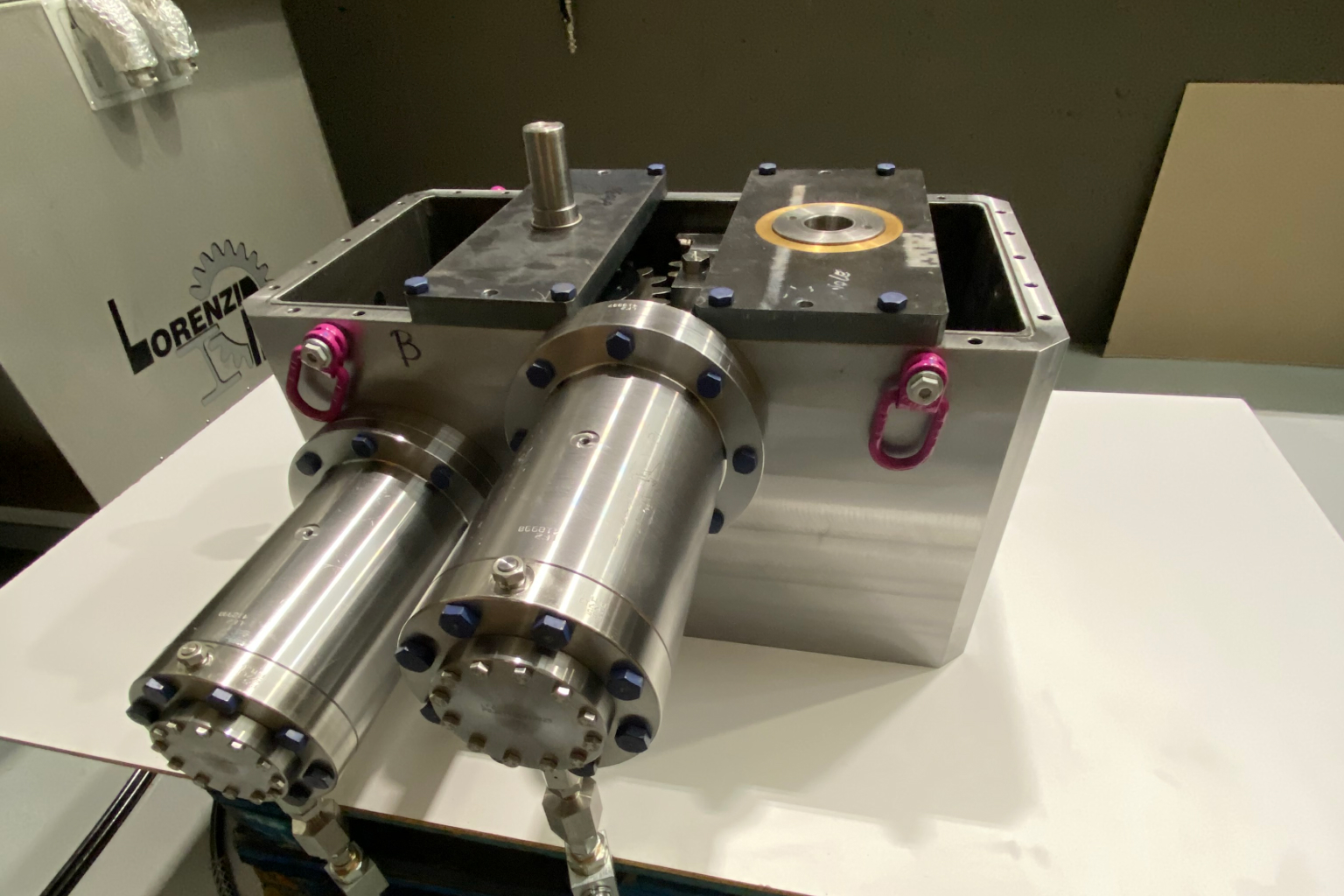

Step Hydraulic Actuator

A special actuator designed in house and mounted on a choke bolted bonnet valve 5.1/8” API 5000 enabling a fine regulation of the flow

Metal Floating Valve for Mining application

Ball Valve in metal to metal configuration designed for self-cleaning anti-corrosion and anti-abrasive service suitable for all severe services including presence of solids such as mining application

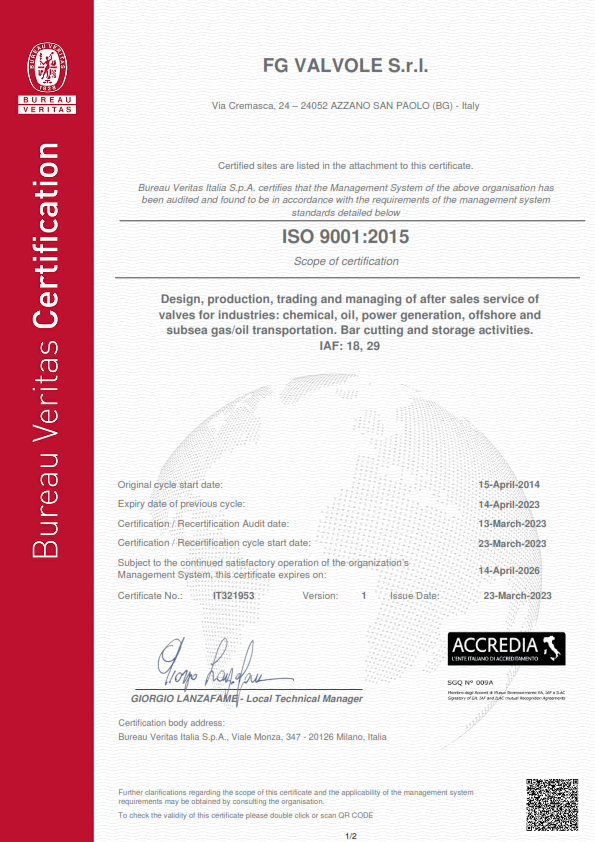

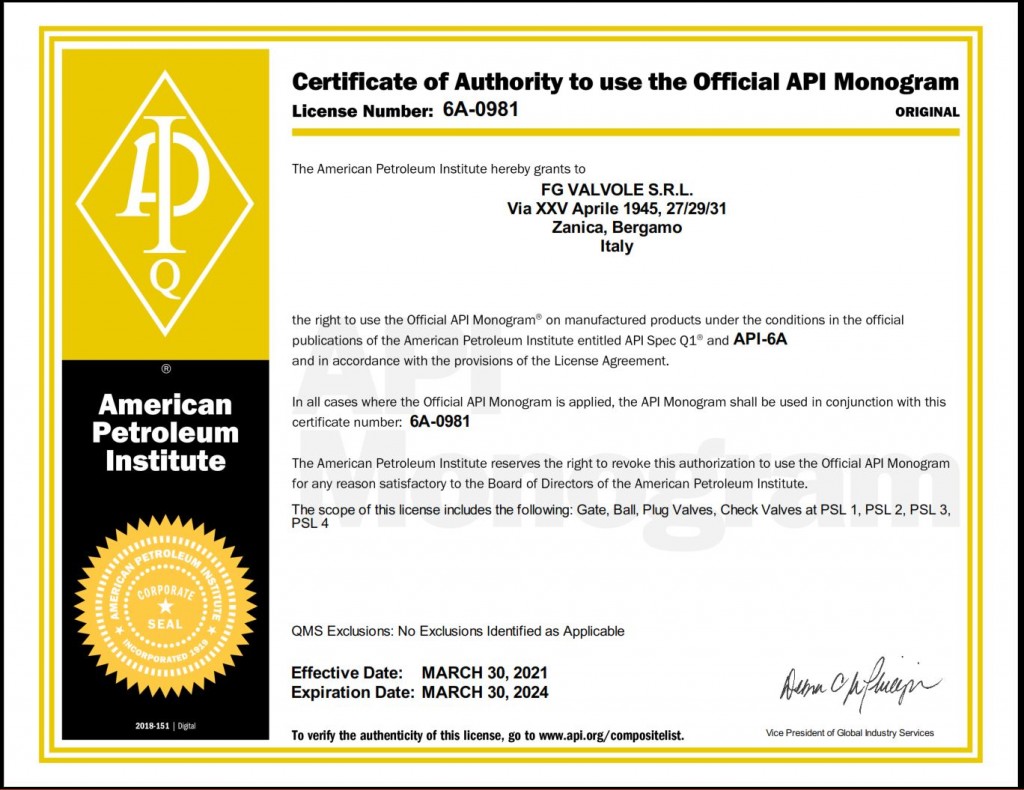

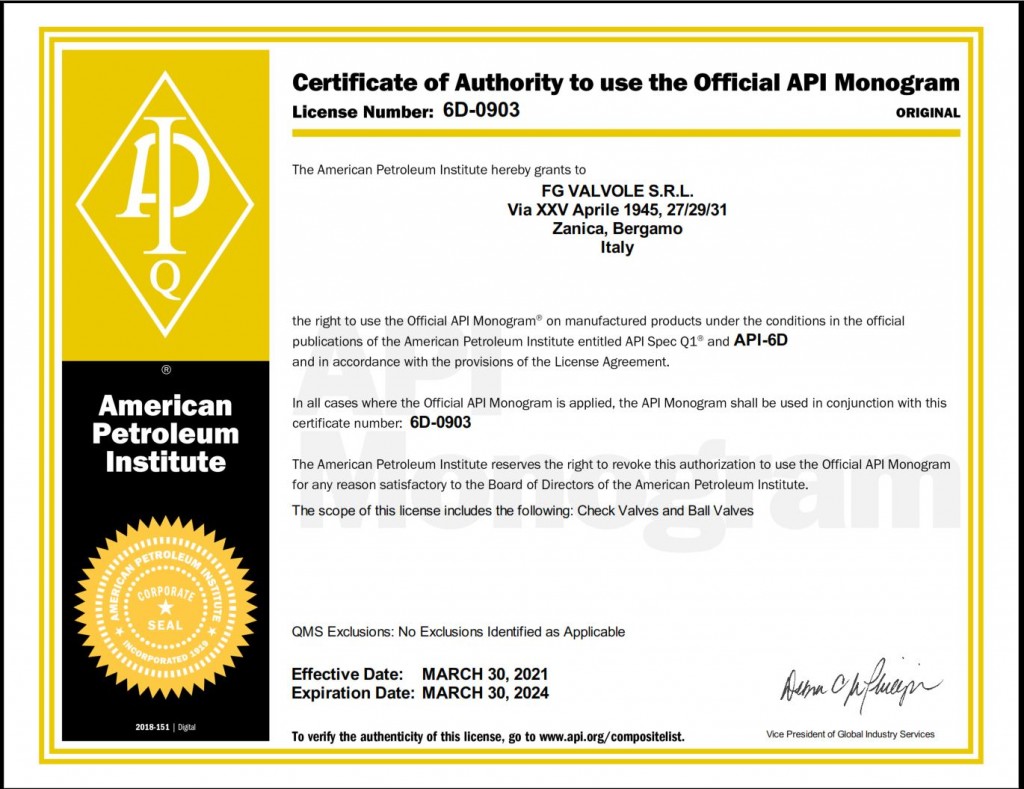

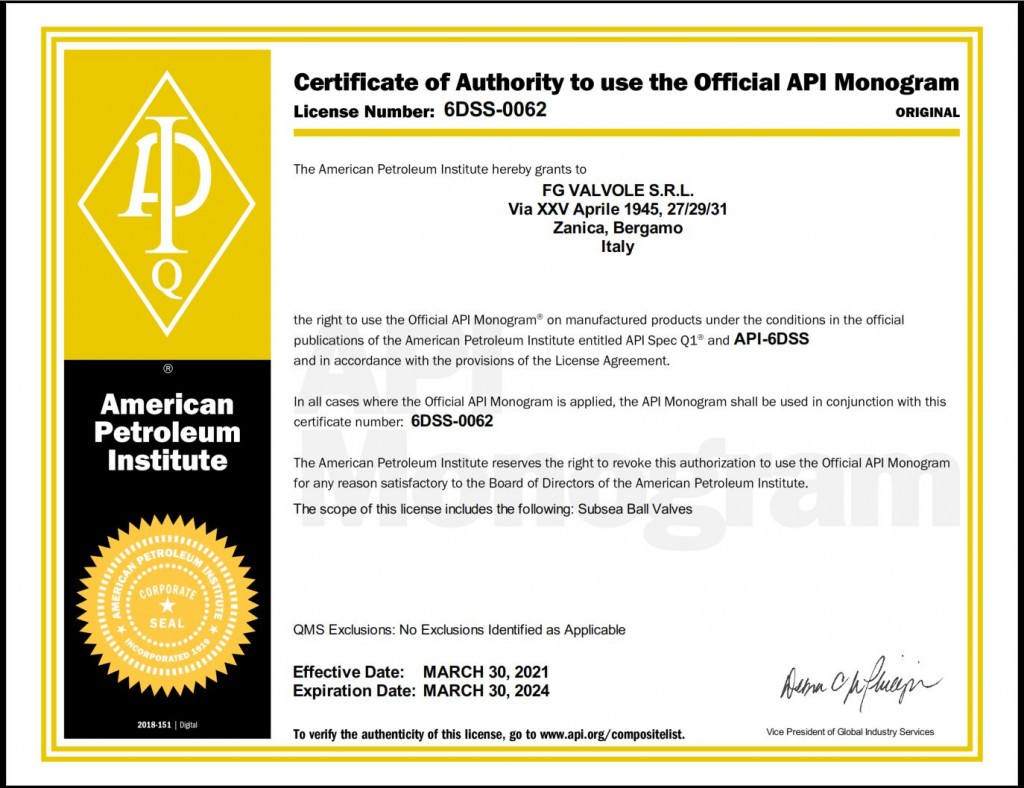

Certifications

FG Valvole believes that the success of the organization depends on the ability to satisfy contractual requirements and Customers’ needs. We are committed to pursuing a policy aimed at putting the Customer at the heart of the activities, by offering and adapting all processes to their needs and requirements. Therefore, FG Valvole Quality Assurance System was created to guarantee the consistent quality expected on an international level. FG Valvole achieves its quality requirements, partly by selecting sub-suppliers able to meet FG Valvole qualification criteria and to consistently execute its activities in accordance with its Quality Assurance System. FG Valvole has achieved the most important system certifications and product licenses and work in compliance with Industry Standard and European directives.

- ISO 14001 SGA certifications on environmental management system

- ISO 45001:2018 occupational health and safety management system

- ISO 9001:2015 Quality Management System certification

- API 6A Monogram n°6A-0981

- API 594 Monogram n°594-0042

- API 6DSS Monogram n°6DSS-0062

- API 6D Monogram n°6D-0903

- API 600 Monogram n°600-0386

- PED – CE-1370-PED-H-FGV 001-20-ITA

- EPIM JQS

- EAC Technical Regulations of Customs Union (TRCU)

- ATEX 2014/34/UE

- SIL level III

- Complete production range is fire safe tested and certified according to API 6FA, API 607, ISO 10497